Bun, Roll, Hot Dog

Perform a complete Vision Quality Control of your product! Thanks to our modular hardware and software architecture, it is possible to configure a Vision Inspection Solution that meets your specific requirements.

Our systems can be used for measurement of 2D shape & size, 3D height, color, topping & surface attributes. A product specific rejection mechanism can be integrated for the automatic removal of defective and out-of-specification products from the production line.

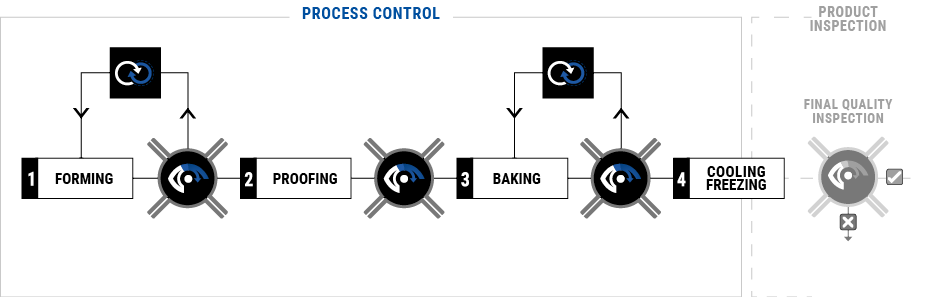

EyeProSystem provides a range of vision system modules designed to monitor a specific production process step.

The measurements taken at each vision module at each point in the line can be collected and displayed at the control station and reported in real time. This data can also be added to a database allowing further analysis and correlation of this data to assist in improving the production process and the quality of the finished product.

Examples of process steps that can be monitored are the following:

- Forming (physical dimensions)

- Proofing (height, scoring)

- Baking (bake color, oven feedback)

By installing an EyePro Vision System at the oven exit, it is possible to integrate our exclusive Real Time Oven Feedback module, which uses the measured bake color to automatically adjust the oven settings.

Key benefits:

- fully automatic control of the last two zones of the oven

- objective bake color measurement

- continuous automatic monitoring of product qualty

- automatic real time actions to correct out of specification situations

- improved product color consistency over the time

- waste reduction

the advantages of Vision Process Control. What about you?